Expert Strategies for Effective Boiler Water Treatment

In the realm of industrial and commercial operations, ensuring the efficient functioning of boiler systems is paramount. One critical aspect of achieving this efficiency is through proper boiler water treatment. This article aims to provide a thorough understanding of boiler water treatment, its significance, methodologies, and how it integrates with effective water purification services.

Understanding Boiler Water Treatment

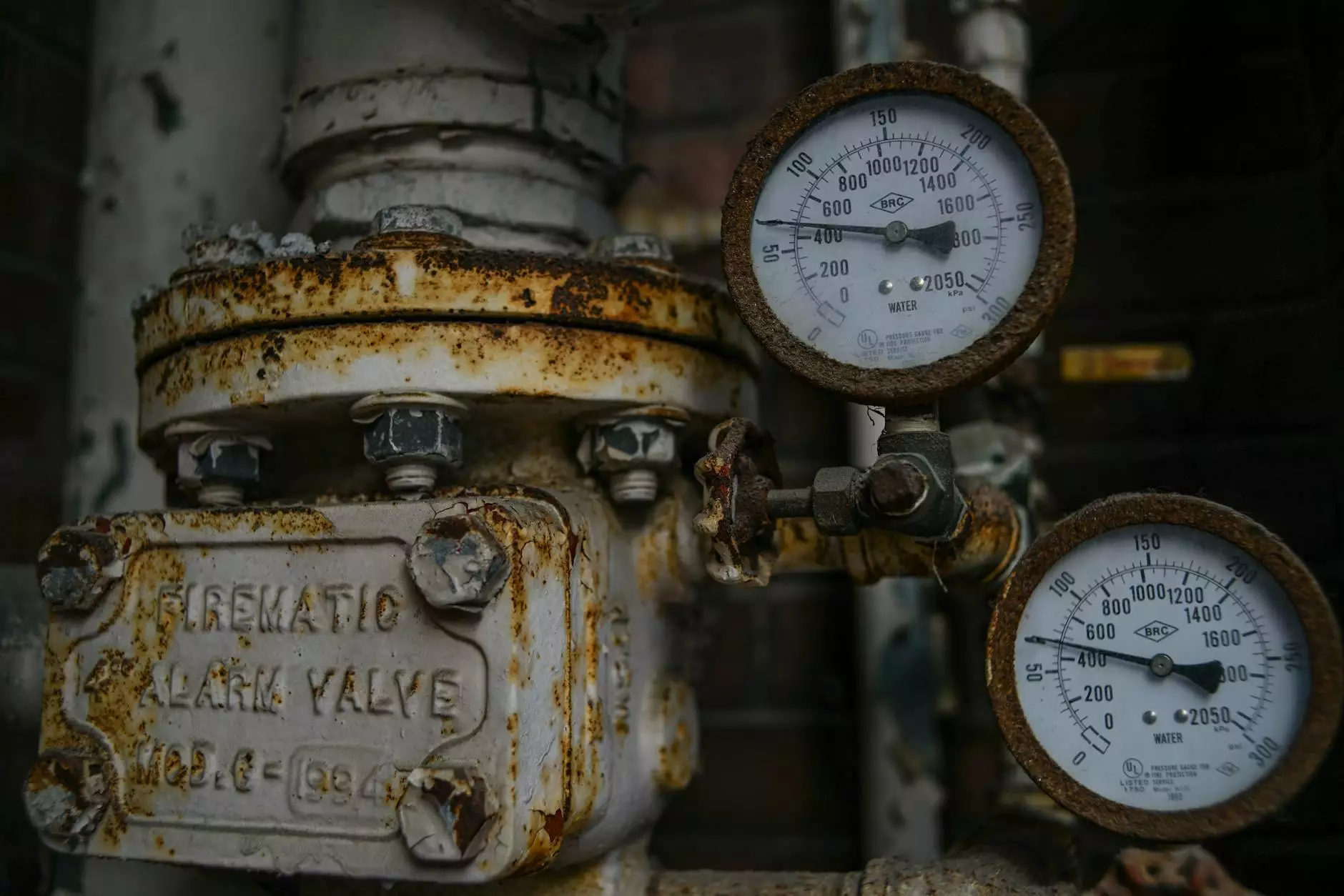

Boiler water treatment encompasses a series of processes and methods aimed at maintaining water quality used in steam-generating boilers. The goal is to prevent corrosion, scale formation, and deposition of impurities, which can hinder boiler efficiency and longevity. Proper management of boiler water significantly impacts operational reliability, maintenance costs, and overall system performance.

The Importance of Boiler Water Treatment

Boiler water treatment is crucial for several reasons:

- Corrosion Prevention: One of the primary goals is to prevent the corrosion of boiler components caused by dissolved oxygen and other aggressive impurities.

- Scale Inhibition: Treatment programs help minimize scale formation which can lead to overheating and boiler failure.

- Enhanced Heat Transfer: Cleaner water ensures better heat transfer efficiency, leading to lower fuel consumption.

- Operational Efficiency: Properly treated water maintains steam quality, which is essential for process industries.

- Compliance with Regulations: Many industries are bound by stringent environmental regulations that require effective water treatment solutions.

Types of Boiler Water Treatment Methods

There are several approaches to boiler water treatment, each tailored to meet specific needs and operational challenges. Here are some of the most common treatment methods:

1. Chemical Treatment

Chemical treatment involves adding specific chemicals to the boiler water to neutralize acids, sequester hardness, and eliminate harmful contaminants. Commonly used chemicals include:

- Sodium Sulfite: Used for oxygen scavenging to prevent corrosion.

- Phosphate: Controls scale formation by precipitating calcium and magnesium.

- Polymeric Dispersants: Help control deposit formation within the boiler.

2. Physical Treatment

This method relies on physical processes to modify water properties. Some effective physical treatment methods include:

- Filtration: Physical removal of particulates and impurities through mechanical filters.

- Ion Exchange: A process where undesirable ions are replaced with non-harmful ions to soften water.

3. Reverse Osmosis (RO)

RO is an advanced filtration method that removes a wide range of impurities, including dissolved salts, by pushing water through a semipermeable membrane. This method is particularly effective in reducing total dissolved solids (TDS).

Choosing the Right Boiler Water Treatment Program

Selecting the right program for boiler water treatment depends on various factors such as the type of boiler, the quality of feed water, and specific operational requirements. Here are some considerations:

- Feed Water Quality: Test incoming water quality to tailor treatment methods accordingly.

- Operational Pressure and Temperature: Understand how operational conditions affect chemical behavior in the boiler.

- System Design: Consider the boiler and piping design as it influences treatment choices.

- Cost-Effectiveness: Analyze the total cost of ownership for treatment solutions, including chemicals and maintenance.

Integrating Boiler Water Treatment with Water Purification Services

Water purification services are essential for ensuring that the feed water used in boiler systems is of high quality. By combining boiler water treatment with effective purification, businesses can achieve optimal performance. Here’s how:

1. Pre-Treatment Processes

Utilizing purification technologies such as filtration and softening as pre-treatment can significantly enhance the effectiveness of boiler water treatment. This step ensures that the water entering the boiler is as free from contaminants as possible.

2. Regular Monitoring

Implementing a rigorous monitoring program to regularly test the quality of both the feed water and boiler water allows for timely adjustments in treatment protocols, thereby maintaining the desired water quality.

3. Utilizing Advanced Technologies

Incorporate advanced purification methods like reverse osmosis or ultrafiltration as part of a holistic approach to boiler water treatment. These technologies can drastically reduce impurities, enhancing overall boiler performance.

Conclusion: Ensuring Longevity and Efficiency

In conclusion, implementing a comprehensive boiler water treatment strategy is vital for any business that relies on steam for operational processes. Focusing on treating water effectively not only mitigates risks associated with boiler failure but also promotes sustainability through improved energy efficiency. By working with experienced water suppliers and leveraging water purification services, enterprises can create a reliable system that adapts to their specific needs.

For your boiler water treatment needs, trust in proven expertise and a commitment to quality service. Explore how our solutions at bimakskimya.com.tr can transform your water management processes and enhance operational efficiency.

Call to Action

Ready to elevate your industrial operations? Contact us today at bimakskimya.com.tr and discover unbeatable water purification services, and expert advice on boiler water treatment tailored to your needs!