Unleashing the Power of China CNC Precision Parts

In the rapidly evolving world of manufacturing, the significance of China CNC precision parts cannot be overstated. Companies globally are acknowledging the advantages of utilizing these high-precision components manufactured through cutting-edge technologies. This article explores the myriad benefits and applications of CNC precision parts, particularly those sourced from China, and how they transform industries worldwide.

Understanding CNC Precision Parts

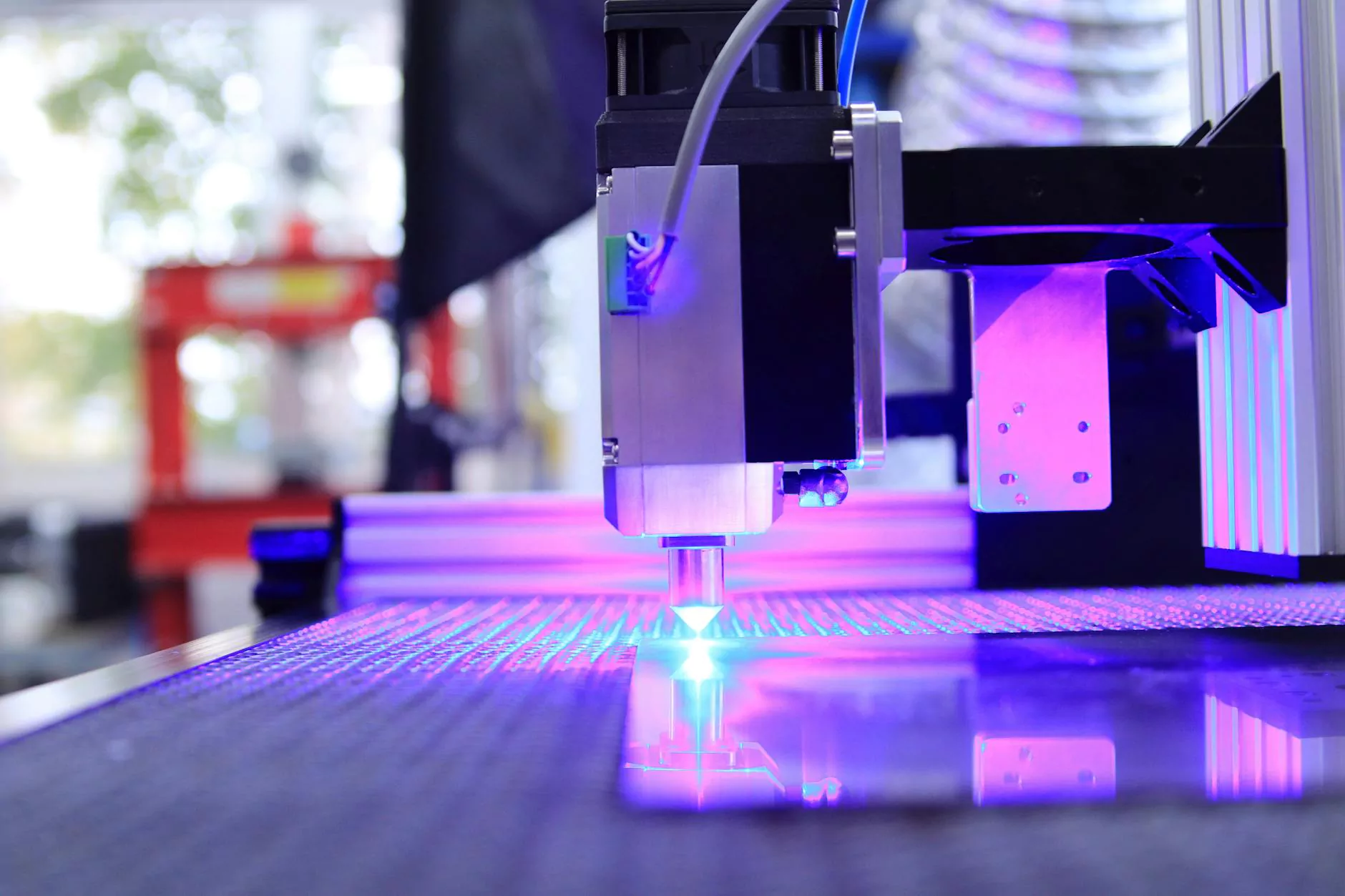

CNC, or Computer Numerical Control, refers to the automated process of using software to control machine tools. This technology enables the high-precision manufacturing of parts, ensuring consistency, accuracy, and efficiency. When we refer to China CNC precision parts, we are talking about components crafted with the utmost precision, ideal for industries ranging from aerospace to automotive.

What Sets China CNC Precision Parts Apart?

China has become a global leader in CNC precision manufacturing due to several key factors:

- Cost-Effective Production: One of the most significant advantages of sourcing CNC parts from China is the cost-effectiveness. The manufacturing processes in China leverage lower labor costs and high technology, resulting in competitive pricing for high-quality parts.

- Advanced Technology: With continuous investment in modern CNC machinery and technology, Chinese manufacturers can produce highly complex components with remarkable precision.

- Skilled Workforce: China boasts a large pool of skilled technicians and engineers trained in CNC programming and operation, further enhancing the quality of the products.

- Flexible Manufacturing: Chinese manufacturers can adapt quickly to changing demands, offering short lead times even for custom production runs.

The Applications of China CNC Precision Parts

The versatility of China CNC precision parts allows their use across various industries:

1. Aerospace Industry

The aerospace sector demands the highest standards of precision and reliability. Parts manufactured using CNC technology, such as brackets, housings, and turbine components, are crucial for the safe and efficient operation of aircraft. Chinese manufacturers produce components that comply with international aerospace standards, ensuring quality and performance.

2. Automotive Industry

The automotive industry relies heavily on CNC precision parts for the production of everything from engine blocks to intricate dashboard components. The precision of these parts leads to better vehicle performance and safety, enhancing the overall driving experience.

3. Medical Equipment

In the medical field, precision is paramount. CNC machined parts are used in medical devices, surgical instruments, and diagnostic equipment, where accuracy can be a matter of life and death. Chinese manufacturers supply a wide range of CNC parts tailored to the specific needs of this sector.

4. Electronics

The electronics industry demands extremely high precision for components such as connectors, housings, and circuit boards. CNC precision parts from China are critical in producing reliable electronic devices that meet consumer expectations for quality and durability.

5. Industrial Equipment

CNC precision parts are essential in constructing industrial machinery. Chinese manufacturers deliver components that enhance machinery performance and longevity, making them a preferred choice for many industrial applications.

Benefits of Choosing China CNC Precision Parts

Opting for China CNC precision parts offers a multitude of benefits for businesses looking to enhance their product offerings:

- Enhanced Quality Control: Many Chinese manufacturers implement rigorous quality control measures to ensure that every component meets exact specifications. This reliability leads to less waste and higher customer satisfaction.

- Innovation and Customization: The ability to create custom parts tailored to specific needs is a significant benefit. Chinese manufacturers often provide engineering support to help design parts that fit unique applications.

- Scalability: As businesses grow, their manufacturing needs may change. Chinese manufacturers can scale production up or down quickly, ensuring that companies can keep pace with market demands.

- Global Logistics Expertise: Many Chinese manufacturers have established logistical networks that streamline the shipping process, minimizing lead times and reducing costs associated with international trade.

Choosing the Right Manufacturer

Selecting the right manufacturer for China CNC precision parts is crucial for ensuring quality and compatibility with your projects. Here are some tips for choosing the right partner:

1. Evaluate Experience and Expertise

Look for manufacturers with a proven track record in CNC machining. Companies with extensive industry experience are more likely to understand your specific needs and produce high-quality parts.

2. Check Certifications

Ensure that the manufacturer holds relevant certifications such as ISO 9001, which denotes quality management standards. Certifications demonstrate a commitment to quality assurance throughout the production process.

3. Review Past Projects

Asking for examples of past projects can provide insight into the manufacturer’s capabilities. Look for case studies or client testimonials that speak to the quality and reliability of their products.

4. Understand Their Technology

Inquire about the types of CNC machinery and software utilized by the manufacturer. Advanced equipment leads to better precision and faster turnaround times.

5. Communication is Key

Effective communication is essential for a successful partnership. Ensure that the manufacturer is responsive, transparent, and willing to collaborate on design and production processes.

Cost Considerations

While China CNC precision parts can be more cost-effective than sourcing locally, it's essential to consider total costs, including shipping, tariffs, and potential delays. A comprehensive cost analysis can help compare options and determine the best value for your specific requirements.

Future Trends in CNC Precision Manufacturing

As technology evolves, so does the landscape of CNC precision manufacturing. Some trends to watch include:

- Automation: The integration of automation and robotics into CNC machining promises to increase efficiency and reduce labor costs further.

- IoT Integration: The Internet of Things (IoT) is set to revolutionize manufacturing by enabling real-time monitoring and optimization of production processes.

- Advanced Materials: The development of new materials, including composites and lightweight alloys, will enhance the capabilities of CNC precision parts.

- Sustainability Practices: Manufacturers are increasingly adopting sustainable practices, focusing on reducing waste and energy consumption in the production process.

Conclusion

In conclusion, the world of China CNC precision parts presents a world of opportunities for manufacturers and businesses seeking high-quality, cost-effective solutions. With a commitment to innovation, quality, and advanced technology, Chinese manufacturers are poised to lead the CNC machining industry into the future.

As you explore the possibilities of sourcing CNC precision parts, consider the immense potential for your business growth. By leveraging the strengths of Chinese manufacturers, you can enhance your product offerings and drive success in an increasingly competitive market.

Get in Touch with DeepMould.net

If you are seeking to enhance your manufacturing capabilities with top-quality China CNC precision parts, look no further than DeepMould.net. Our commitment to excellence and industry-leading technologies will ensure that you receive the best components tailored to your specific needs.